We take a bottom-line approach to each project. Our clients consistently see increased traffic, enhanced brand loyalty and new leads thanks to our work.

The Positive Material Identification (PMI) is an analytical technique that has the aim to clearly recognize a material. In mechanic industry it is an identification testing of metal alloys needed to prevent the misuse of parts, materials and welding electrodes that could cause extensive damage.

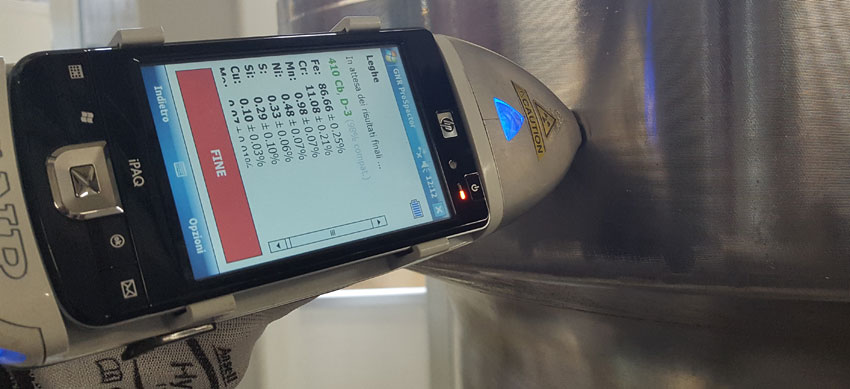

Two techniques are mainly used:

At Metalprove S.r.l. both types of PMI instruments are available and are used daily at the customer premises, depending on the needs or specifications to be fulfilled. It has to be noticed that some elements such as carbon, boron and silicon are invisible to the XRF technique and can be measured only by a OES instrument. The optical emission spectrometer, however, leaves small traces on the test surface because of the discharges, and it is therefore not recommended on items with good surface finish.